Added to Cart!

Message

Get to Know Your Knife “Designed for Performance … Built For Extremes.” Straightforward design, precision engineering and high-resolution components, combined with state of the art aerospace-qualified manufacturing facility embody our search for constant evolution and manufacturing excellence.

All of our knives are manufactured at our facility in Los Angeles, California from the highest grade American made materials.

Emerson Knives have proven themselves in the most hostile environments on the planet. From the extreme limits of outer space to the blackest depths of the ocean, in steaming jungle rain forests and on the icy granite walls of the world tallest mountains. They have been called to task, and have withstood the test.

Get to Know Your Knife “Designed for Performance … Built For Extremes.” Straightforward design, precision engineering and high-resolution components, combined with state of the art aerospace-qualified manufacturing facility embody our search for constant evolution and manufacturing excellence.

All of our knives are manufactured at our facility in Los Angeles, California from the highest grade American made materials.

Emerson Knives have proven themselves in the most hostile environments on the planet. From the extreme limits of outer space to the blackest depths of the ocean, in steaming jungle rain forests and on the icy granite walls of the world tallest mountains. They have been called to task, and have withstood the test.

Blades: All of our blades are made with 154CM Steel, a premium grade American made stainless. The blades measure .125 inch in thickness and are heat treated to a Rockwell hardness of 57-59.

Finishes: Black blades are coated with a black Teflon coating.

Stonewash blades are finished using a special media during the tumbling process. This finish creates an attractive surface which helps hide signs of use and wear on the blade.

Handles: Emerson Knife handles are made from G-10, a glass filled epoxy laminate. Some models are available with different colors of G-10.

Blades: All of our blades are made with 154CM Steel, a premium grade American made stainless. The blades measure .125 inch in thickness and are heat treated to a Rockwell hardness of 57-59.

Finishes: Black blades are coated with a black Teflon coating.

Stonewash blades are finished using a special media during the tumbling process. This finish creates an attractive surface which helps hide signs of use and wear on the blade.

Handles: Emerson Knife handles are made from G-10, a glass filled epoxy laminate. Some models are available with different colors of G-10.

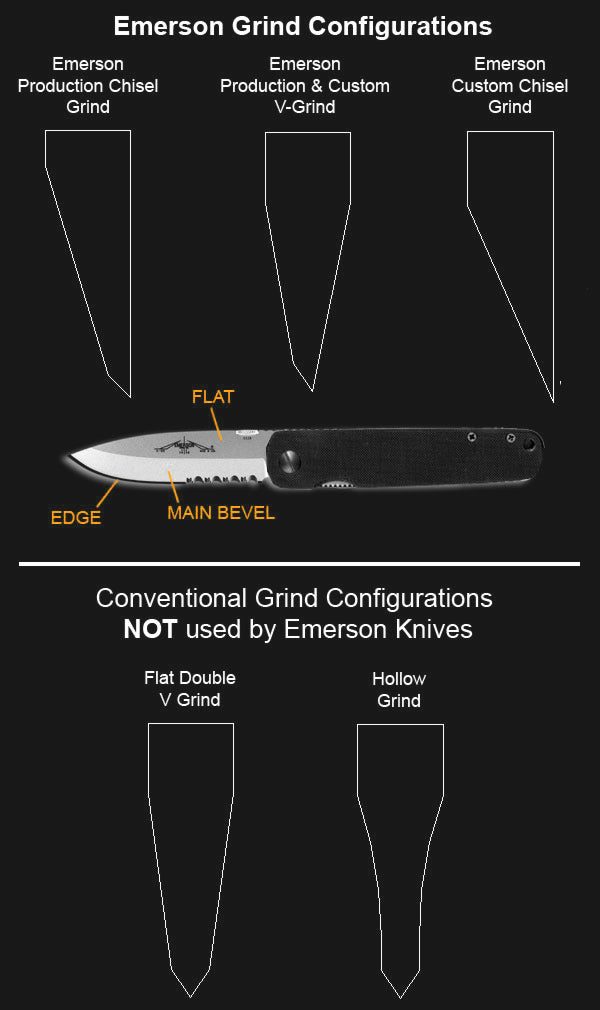

From time to time we get a question like “Hey you forgot to grind the other side of my knife! It’s only sharpened on one side!”Well, the simple answer is this; that’s the way it’s supposed to be. I developed the Emerson single side edge after years of test, evaluation, research and feedback. I’ve been doing this for over thirty years now regardless of what type of level grind is on the knife, double V or chisel, I only grind the edge(the sharpest) of the knife on one side. It produces an extremely sharp; very durable and easy to service (sharpen) edge for hard duty use.

The main difficulty anyone ever has with our grinds is this, “I’m used to knives sharpened on both sides.” I understand, as that s the way most conventional knives are sharpened. However, once you break that mind-set, you will find that the Emerson Edge grind (one side only) cuts like crazy, stays sharp and is much easier to sharpen back to cutting capability.

Because, you’re only dealing with one edge, not two. I’ve sharpened these knives on rocks, bricks, pieces of pipe, sandpaper, glass and stones of all types and I’ve never had a problem getting a good using edge. Yes, I admit if I sharpened it on a piece of concrete, wouldn’t shave with it, but, I have a razor for that.

From time to time we get a question like “Hey you forgot to grind the other side of my knife! It’s only sharpened on one side!”Well, the simple answer is this; that’s the way it’s supposed to be. I developed the Emerson single side edge after years of test, evaluation, research and feedback. I’ve been doing this for over thirty years now regardless of what type of level grind is on the knife, double V or chisel, I only grind the edge(the sharpest) of the knife on one side. It produces an extremely sharp; very durable and easy to service (sharpen) edge for hard duty use.

The main difficulty anyone ever has with our grinds is this, “I’m used to knives sharpened on both sides.” I understand, as that s the way most conventional knives are sharpened. However, once you break that mind-set, you will find that the Emerson Edge grind (one side only) cuts like crazy, stays sharp and is much easier to sharpen back to cutting capability.

Because, you’re only dealing with one edge, not two. I’ve sharpened these knives on rocks, bricks, pieces of pipe, sandpaper, glass and stones of all types and I’ve never had a problem getting a good using edge. Yes, I admit if I sharpened it on a piece of concrete, wouldn’t shave with it, but, I have a razor for that.

By the way, if you think of the sharpest piece of steel in your house, what is it? No, it is not your kitchen knives; it is not your pocket knife. It is the razor that you shave with every morning. It doesn’t matter if it's Schick, Gillette or BIC they are the sharpest blades in your house. Guess how they are sharpened? One side only – exactly like an Emerson Knife.

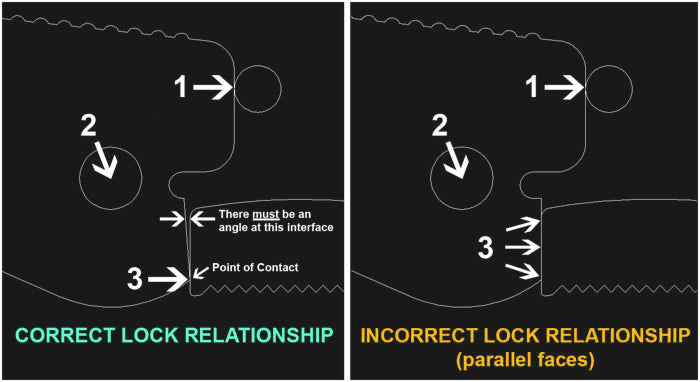

Liner Locks are comprised of a three point contact system. The three points are:

1. Point where the blade contacts the stop pin.

2. The center point of the pivot bolt.

3. The point where the liner contacts the bottom edge of the blade ramp.

By the way, if you think of the sharpest piece of steel in your house, what is it? No, it is not your kitchen knives; it is not your pocket knife. It is the razor that you shave with every morning. It doesn’t matter if it's Schick, Gillette or BIC they are the sharpest blades in your house. Guess how they are sharpened? One side only – exactly like an Emerson Knife.

Liner Locks are comprised of a three point contact system. The three points are:

1. Point where the blade contacts the stop pin.

2. The center point of the pivot bolt.

3. The point where the liner contacts the bottom edge of the blade ramp.

Note: There must be an angle between the blade lock ramp and the face of the liner lock to create the three point lock structure and relationship. The face of the lock and the face of the liner are not parallel.

Cheap Chinese imports and others who do not understand the mechanics of the liner lock system may think that the lock face on the blade and the face of the liner lock should be parallel, face to face, with full engagement of the lock face against the back of the blade. They are incorrect. As both aerospace mechanical Engineer and the third knife maker in the world to use the liner lock system almost thirty years ago, and having made several thousand custom knives and several hundred thousand production knives I assure you that I know of what I speak.

Note: There must be an angle between the blade lock ramp and the face of the liner lock to create the three point lock structure and relationship. The face of the lock and the face of the liner are not parallel.

Cheap Chinese imports and others who do not understand the mechanics of the liner lock system may think that the lock face on the blade and the face of the liner lock should be parallel, face to face, with full engagement of the lock face against the back of the blade. They are incorrect. As both aerospace mechanical Engineer and the third knife maker in the world to use the liner lock system almost thirty years ago, and having made several thousand custom knives and several hundred thousand production knives I assure you that I know of what I speak.